Choosing the right door solution for your space—whether it’s for a high-security commercial property, warehouse, or residential garage—can significantly impact both functionality and aesthetics. Rolling shutter doors and sectional doors each offer distinct benefits tailored to specific needs.

In this article, we will explore the key differences between rolling shutter doors vs sectional doors, focusing on factors such as speed, security, energy efficiency, and cost. We aim to provide a clear comparison, helping you make an informed decision based on your unique requirements. But before determining which type of door is more suitable for your building and operation, let’s first take a look at these differences.

Contents

- 1 What is a Rolling Shutter Door?

- 2 What is a Sectional Door?

- 3 Rolling Shutter Doors vs Sectional Doors: Technical Comparison

- 4 Key Differences Between Rolling Shutter Doors and Sectional Doors

- 5 At a Glance of Key Differences: Rolling Shutter Doors vs. Sectional Doors

- 6 Cost Comparison: Rolling Shutter vs Sectional Door

- 7 Applications and Best Use Cases: Rolling Shutter Doors vs Sectional Doors

- 8 Which Door Should You Choose? Rolling Shutter Doors vs Sectional Doors

- 9 Conclusion

- 10 Frequently Asked Questions

- 10.1 Is a garage door rolling vs sectional better for a small garage?

- 10.2 How do roll-up doors compare to sectional steel doors for commercial door use?

- 10.3 What are the maintenance differences between a roller shutter door and a sectional garage door?

- 10.4 Which is more insulated: steel garage door roll-up vs sectional steel garage doors?

- 10.5 Do rolling and sectional doors differ in space they take up when open?

- 10.6 Which option is more cost-effective: rolling garage door or sectional steel garage doors?

- 10.7 Are roller door systems or sectional garage doors better for loading docks and heavy use?

- 10.8 How do security and safety compare between a roller shutter door and a sectional steel door?

What is a Rolling Shutter Door?

Definition and Features

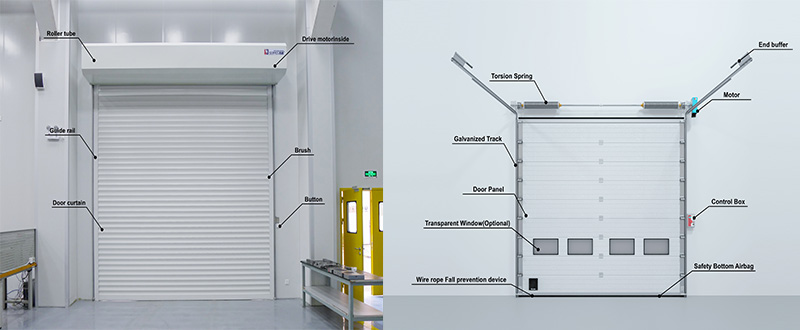

Automatic rolling shutter doors consist of horizontal slats or panels that roll up and down around a drum or roller positioned above the opening. Typically made from steel, aluminum, or a combination of materials, rolling shutter doors are durable, secure, and compact.

These steel rolling doors are commonly used in commercial, industrial, and residential settings. They can be operated manually or electrically, and offer customization in materials, sizes, and appearance to meet specific security or aesthetic needs. Their space-saving design makes them ideal for areas with limited overhead clearance, providing an efficient solution for access control.

Advantages of Rolling Steel Shutter Doors

Space Efficiency

Rolling steel shutter doors are known for their compact design. Unlike traditional swing doors or sectional doors, which require significant space to open, rolling shutters roll up into a neat coil at the top of the opening, saving valuable space both inside and outside. This makes them perfect for tight spaces or locations with limited headroom.

Their vertical operation minimizes the need for wide clearance, making them ideal for narrow aisles or areas with limited room.

Durability and Security

- Strength of Construction: Rolling steel shutter doors are built from durable materials like steel or aluminum. It can offer strong, long-lasting protection against break-ins and extreme conditions.

- High-Security Requirements: Due to their design, rolling shutters offer a high level of security against unauthorized entry. The interlocking slats create a strong barrier, making it harder for intruders to force their way through.

- Weather Resistance: Rolling shutter doors offer weather resistance, protecting against heavy rain, strong winds, and extreme temperatures, making them ideal for warehouses, garages, and storefronts.

What is a Sectional Door?

Definition and Features

Industrial sectional overhead doors consist of multiple hinged panels that slide upwards along tracks to open, making it space-efficient, as it doesn’t require outward clearance. Typically made from steel or aluminum, these doors offer durability, excellent insulation, and enhanced security. With weather seals to prevent dust, water, and pests, sectional doors are ideal for both residential and commercial applications.

Advantages of Sectional Doors

Insulation

One of the key advantages of sectional doors is their superior thermal insulation. The panels are often filled with materials such as polyurethane or polystyrene, which help reduce heat transfer. This makes sectional doors an excellent choice for spaces where maintaining a stable temperature is crucial, such as cold storage facilities, warehouses, and residential garages.

Flexibility in Size and Customization Options

- Tailored Fit: Sectional doors can be customized to fit various opening sizes, whether it’s for a residential garage or a large industrial warehouse. It makes sectional doors a flexible solution for many applications.

- Panel Design: The sectional overhead door can also be customized, with options for different finishes, colors, and materials (e.g. steel or aluminum). This flexibility makes them suitable for everything from sleek modern homes to industrial complexes.

- Motorization Options: Sectional lifting doors are available with motorized or automated systems. And it can offer remote control, which is ideal for high-traffic areas and businesses that require efficient access.

Rolling Shutter Doors vs Sectional Doors: Technical Comparison

| Feature | Rolling Shutter Door | Sectional Door |

|---|---|---|

| Insulation | Low to moderate | Excellent (40–80mm insulated panels) |

| Security | Very high | Moderate to high |

| Opening Speed | Slow to medium | Medium to fast |

| Maintenance | Low daily / higher repair cost | Moderate daily / easy repair |

| Energy Efficiency | Lower | High |

| Initial Cost | Lower | Medium to high |

| Best For | Security & low headroom | Insulation & climate control |

Key Differences Between Rolling Shutter Doors and Sectional Doors

Design and Construction Features

Rolling Shutter Doors:

- Design: Rolling shutter doors consist of horizontal slats or panels that interlock, creating a flexible and strong surface. These doors roll up into a compact coil or drum, typically located above the opening. The slats are usually made of steel, aluminum, or a combination of materials, providing excellent strength and security.

- Construction: The construction is relatively simple and designed for compactness. The slats’ interlocking mechanism allows the door to roll smoothly, minimizing the space required for the door’s operation.

Industrial Sectional Doors:

- Design: Sectional doors are made up of multiple horizontal panels connected with hinges. These panels are typically made of steel or aluminum, and are often filled with insulating material. The door opens vertically and is guided along tracks.

- Construction: The sections of the door allow flexibility in design and size, which is particularly useful for varying door openings. The panels are typically rigid and reinforced, offering durability and insulation. Sectional doors tend to be bulkier compared to rolling shutters, but offer superior insulation properties.

Operation Mechanism Comparison

Rolling Shutter Doors:

- Mechanism: Rolling shutter doors operate by rolling the slats up and down around a drum or barrel located above the opening. This mechanism is typically motorized.

- Speed: They tend to open and close quickly, making them ideal for high-traffic environments where rapid access is needed, such as in retail stores, parking garages, or loading docks.

- Space Efficiency: Since the door rolls up and stores neatly in a compact coil, it requires minimal overhead space, making it ideal for areas where headroom is limited.

Sectional Doors:

- Mechanism: Sectional doors operate by sliding upward along tracks with a set of interconnected panels. The panels move vertically and are either manually operated or motorized.

- Speed: The opening and closing process is generally slower than rolling shutters due to the complexity of the track system and panel movement.

- Space Efficiency: Sectional doors need more clearance above the opening for the tracks and panels to move. Although they don’t need clearance beyond the door’s perimeter, they require more vertical space than rolling shutter doors.

Durability and Maintenance Considerations

Rolling Shutter Doors:

- Durability: Built for maximum security. Constructed from galvanised steel or aluminium, these doors offer exceptional resistance to physical impact, forced entry, and harsh weather conditions. They are the preferred choice for high-risk industrial environments.

- Maintenance: Focuses on the mechanical coiling system. While the curtain is robust, the motor, guides, and interlocking slats require periodic lubrication to prevent friction. Routine inspections are essential to check for slat misalignment or corrosion in coastal areas.

Sectional Doors:

- Durability: Designed for stability and climate control. The rigid, reinforced insulated panels are highly durable against wind pressure and temperature extremes. While the panels are strong, the door relies on a complex system of tracks and rollers.

- Maintenance: Requires a strictly disciplined schedule. Due to the number of moving parts—hinges, torsion springs, and cables—sectional doors need frequent lubrication and tensioning. However, a key advantage is that individual panels can be replaced cheaply if damaged by a forklift, unlike the complex repair of a shutter curtain.

At a Glance of Key Differences: Rolling Shutter Doors vs. Sectional Doors

| Door Type | Insulation (U-Value) | Security & Durability | Opening Speed | Maintenance & Repair | Cost Profile |

| Rolling Shutter Door | Low to Moderate. Standard slats have no insulation. “Insulated” models exist, but suffer from thermal bridging at every interlocking slat joint. | High. Galvanized steel slats are difficult to cut or pry open. Excellent resistance to forced entry and high wind loads. | Slow. Standard motors operate slowly to coil the heavy curtain. (High-speed fabric options exist, but offer lower security). | Low Daily / High Repair. Few moving parts mean less daily wear. However, if a forklift hits the curtain, replacing the damaged coil can be expensive and difficult. | Low Upfront. Generally the most budget-friendly option for installation, but higher long-term energy costs due to heat loss. |

| Sectional Door | Excellent. Large panels (40mm–80mm) filled with polyurethane foam offer superior thermal efficiency and air tightness. | Moderate. Secure for general use, but hinges and rollers can be vulnerable points compared to a solid steel curtain. | Medium. Slides up and back efficiently. Often compatible with faster motors for optimized traffic flow in busy warehouses. | Moderate Daily / Easy Repair. Springs and cables require regular tensioning. However, damaged panels can be swapped out individually and cheaply. | Medium Upfront. Higher initial investment for tracks and panels, but offers significant ROI through energy savings and climate control. |

Cost Comparison: Rolling Shutter vs Sectional Door

| Cost Factor | Rolling Shutter Doors | Sectional Doors |

|---|---|---|

| Initial Investment | Lower upfront cost | Higher upfront cost due to complexity and insulation |

| Maintenance | Moderate; more frequent maintenance of moving parts | Lower maintenance costs; fewer parts to wear out |

| Repairs & Lifespan | 10-20 years; damage to individual slats may require replacement of the entire door | 20-30 years; individual panels can be replaced without replacing the entire door |

| Energy Efficiency | Lower insulation; higher energy costs in extreme climates | Higher insulation; energy savings over time |

Applications and Best Use Cases: Rolling Shutter Doors vs Sectional Doors

Ideal Environments for Insulated Rolling Shutter Doors

Rolling shutters are the popular product of the industrial world. They excel in tough, high-security, or space-constrained environments where aesthetics are secondary to function.

High-Security Loading Docks

Why: The interlocking galvanized steel slats act as a continuous metal wall, making them highly resistant to angle grinders and crowbars.

Best Use: Remote warehouses, bonded storage facilities, and rear retail loading bays where overnight security is paramount.

Low-Headroom Facilities

Why: If your facility has low ceilings or overhead obstructions like bridge cranes, sprinkler pipes, or HVAC ducts, rolling shutters are the only viable option. They require zero “backroom” depth, coiling compactly into a box above the opening.

Best Use: Older manufacturing plants and basements.

Heavy Industry & Manufacturing

Why: In environments with dust, welding sparks, or heavy vibration, the simple mechanical design of a shutter (fewer plastic parts) is more robust than a sectional door’s hinges and rollers.

Best Environments for Sectional Doors

Sectional doors are the smart product of industrial access. They are the superior choice where climate control, light, and workflow efficiency are critical.

Cold Storage & Food Logistics

Why: This is the use case for sectional doors. With 40mm–80mm thick polyurethane foam panels, they effectively break the thermal bridge. A insulated sectional door can maintain a stable internal temperature in a freezer warehouse (-25°C), slashing energy bills by up to 30% compared to a shutter.

Best Use: Refrigerated distribution centers, food processing plants, and pharmaceutical storage.

Fire Stations & Emergency Depots

Why: Reliability and speed are key. Modern “High-Speed Sectional Doors” can open at 1.5+ meters/second. Furthermore, the ability to add Full-Vision (glazed) panels allows drivers to see traffic conditions outside before exiting, preventing accidents.

Best Use: Fire stations, ambulance bays, and car dealerships.

Cleanrooms & Pharmaceutical Production

Why: Standard rolling shutters have thousands of crevices (between slats) that trap dust and bacteria. Sectional doors have large, smooth, flat surfaces that are easy to wipe down and sanitize.

Best Use: GMP-compliant facilities, laboratories, and electronics manufacturing.

Commercial Showrooms

Why: Aesthetics matter. A sectional door can be customized with powder-coated finishes, panoramic windows, and sleek styling that looks inviting rather than “industrial.”

Best Use: Car repair shops, retail warehouses, and commercial garages.

Which Door Should You Choose? Rolling Shutter Doors vs Sectional Doors

Choose a Rolling Shutter if

Headroom or Ceiling Space is Restricted

If your facility has overhead obstructions—such as bridge cranes, sprinkler systems, or high-bay lighting—a rolling shutter is the ideal solution. Because the curtain coils tightly into a box directly above the opening (typically requiring only 400mm–600mm of vertical space), it leaves the ceiling area completely free, unlike the long horizontal tracks required for sectional doors.

Maximum Security is the Priority

For high-risk areas, the rolling shutter is the industry standard for physical protection. The interlocking galvanized steel slats form a continuous, double-skinned metal wall that is exceptionally difficult to pry open or penetrate. With no external hinges or cables to cut, they offer a formidable deterrent against forced entry.

Budget is the Primary Constraint

If low upfront capital expenditure (CapEx) is your main driver, rolling shutters generally offer a lower price point. Their simpler design—consisting of a curtain, guides, and barrel—means faster installation times and lower initial material costs compared to the complex panel-and-track systems of sectional doors.

Choose a Sectional Door if

Thermal Insulation is Critical

For food logistics, pharmaceuticals, or heated warehouses, sectional doors are the undisputed winner. Their 40mm–80mm foam-filled panels and full-perimeter seals can achieve U-values as low as 0.5 W/m²K, significantly reducing energy loss. In contrast, standard rolling shutters suffer from thermal bridging at every slat joint.

You Need Natural Light & Visibility

Sectional doors allow for the integration of large, double-glazed vision panels or full-vision aluminium sections. This introduces natural daylight into the workspace—reducing electricity bills—and improves safety by allowing forklift drivers to see oncoming traffic before the door opens.

Quiet Operation & Aesthetics Matter

If the door faces a customer area (like a car showroom or retail warehouse), the “visual feel” is crucial. Sectional doors offer a clean, premium appearance with smooth, quiet operation thanks to nylon rollers. They eliminate the loud, metallic rattle typical of rolling shutters, creating a more professional and comfortable working environment.

Conclusion

In my professional experience, the choice between a rolling shutter and a sectional door—it is about what your facility values most right now.

If you asked me to secure a facility with limited headroom, a strict budget, or a high risk of break-ins, I would recommend the rolling shutter every time. It remains the industry’s “workhorse”—rugged, compact, and undeniably secure.

However, if your goal is to reduce long-term energy costs, improve the working environment, or maintain strict temperature control (such as in food logistics). I strongly suggest investing in a sectional door.

Frequently Asked Questions

Is a garage door rolling vs sectional better for a small garage?

For smaller garages, a sectional garage door often provides a small footprint because its panels bend and sit parallel to the ceiling, making it a common choice for smaller garages where low-headroom is an issue. Rolling garage door (roller door) systems are also cost-effective and require less space in front of the opening, but they take up vertical space above the entryway. The best fit depends on exact dimensions, whether you need insulation, and whether doors require routine maintenance in a tight area.

How do roll-up doors compare to sectional steel doors for commercial door use?

Roll-up doors (rolling steel door) and sectional steel doors both serve commercial and industrial settings, but they have different strengths: roll-up doors are durable, handle heavy usage well, and are ideal for loading docks and high-performance environments, while sectional steel garage doors offer better insulation options and quieter operation. Commercial overhead doors are chosen based on specific application, size and weight, fire-rated needs, and whether doors typically need rapid cycles or thermal efficiency.

What are the maintenance differences between a roller shutter door and a sectional garage door?

Roller shutter doors generally require less maintenance on the track because they roll into a compact coil, but their springs and drum can need periodic service. Sectional garage doors have hinges and tracks along the ceiling or roof and may require lubrication and adjustment more frequently. Doors require routine inspection for wear on springs, cables, and seals; a reliable door company can advise intervals based on heavy use or commercial and industrial duty cycles.

Which is more insulated: steel garage door roll-up vs sectional steel garage doors?

Sectional steel garage doors typically provide better insulation because insulation panels can be integrated between the sections (double-skinned steel sectional doors), making them suitable where climate control or energy efficiency matters. Roll-up doors can be insulated but often have less continuous insulation because of the coiling action; for applications needing high-performance thermal control, insulated sectional garage doors are usually the best fit.

Do rolling and sectional doors differ in space they take up when open?

Yes, steel rolling shutter doors coil above the opening, saving ceiling space, but may need more headroom. Sectional lifting doors slide along the ceiling, requiring space overhead, but leaving the vertical opening clear. The choice depends on whether you prioritize headroom or ceiling space.

Which option is more cost-effective: rolling garage door or sectional steel garage doors?

Generally cheaper upfront options are rolling garage doors for simple, smaller openings, but costs vary by materials, insulation, and automation. Sectional vs roller price comparisons should include lifecycle costs: sectional garage doors may reduce energy bills if insulated, and they can be more secure and quieter. Evaluate cost-effectiveness by considering initial price, long-term maintenance, and whether doors require specific features like fire-rated construction or high-performance operation.

Are roller door systems or sectional garage doors better for loading docks and heavy use?

For loading docks and heavy use, roll-up doors are often favored because they handle frequent cycles and tough conditions well; high-performance commercial roll-up doors can be fast-operating and durable. However, heavy-duty sectional steel doors can also serve industrial settings, especially where insulation, security, and larger panel sizes are needed. Consider types of commercial traffic, exact dimensions, and whether doors require fire-rated or security features.

How do security and safety compare between a roller shutter door and a sectional steel door?

Both roller shutter doors and sectional steel doors can be highly secure when built from quality steel and fitted with proper locks and automation. Roller doors offer a continuous curtain that resists forced entry and is popular for storefronts and farm buildings, while steel sectional doors can include reinforced panels and safety sensors. Safety features, such as auto-reverse and breakaway protection, should be standard regardless of whether you choose roll-up vs sectional solutions.