In modern manufacturing and the food industry, effectively maintaining cleanliness and temperature control within the workshop has become a key indicator of a company’s modern management level. Many factories spend considerable effort on internal cleaning, yet often overlook the biggest issue—the frequently opened warehouse entrance doors. Industrial sectional doors and air curtains, work in intelligent linkage to achieve efficient environmental control. Which providing a solution to create a clean, energy-saving, and efficient factory environment. This article will explore the significance of the linkage between industrial sectional doors and air curtains.

Contents

- 1 The Environmental Control Dilemma at Factory Entrances: Why Traditional Solutions Fall Short

- 2 Sectional Door & Air Curtain:How is the Synergistic Effect of 1+1 > 2 Achieved?

- 3 Core Advantages of the Combo Solution: Elevating Factory Operational Standards

- 4 FAQ

- 4.1 Q: Is sectional overhead door linked system with an air curtain really better than using an air curtain alone?

- 4.2 Q: Our factory is a GMP pharmaceutical plant, can this linkage system meet our cleanliness and compliance requirements?

- 4.3 Q: For cleanroom entrances in semiconductor factories, does this linked system provide ESD protection?

- 4.4 Q: Will air curtains be noisy enough to affect the workshop working environment?

The Environmental Control Dilemma at Factory Entrances: Why Traditional Solutions Fall Short

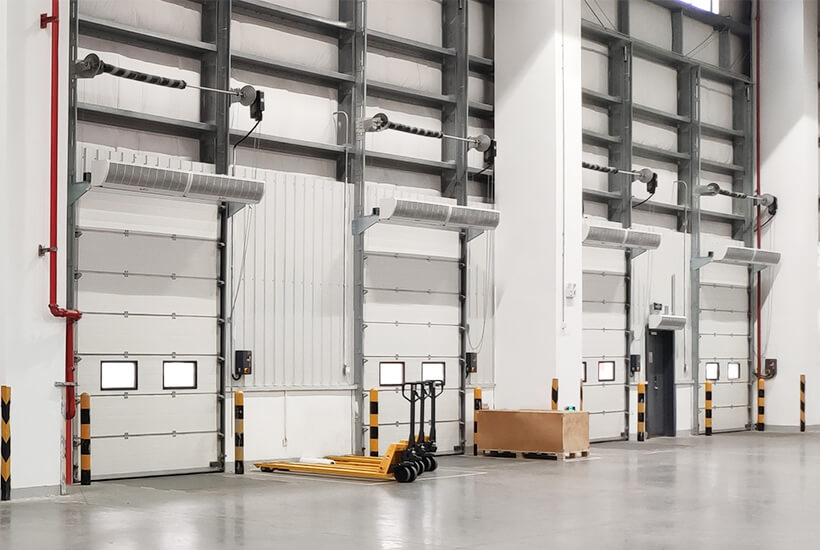

Pollution ingress and egress during opening

In traditional factory entrance and exit management, industrial sectional overhead doors become an entry point for external pollutants during opening. Particularly in the case of dust, insects, exhaust fumes, willow flakes etc. For industries such as food, pharmaceuticals and precision electronics, Where air cleanliness control is critical, any introduction of external contaminants can lead to substandard products in the manufacturing process.

Impact Analysis: When a insulated sectional door is opened, the air inside the workshop is exchanged directly with the outside environment, resulting in the entry of dust, foreign matter, etc. The air in the workshop can be directly exchanged with the outside environment, resulting in the entry of dust and foreign matter. These problems are particularly acute in food processing plants, pharmaceutical factories, and electronics manufacturing plants. Because of the high level of cleanliness required in these industries, external contamination can lead to quality issues or regulatory non-compliance.

Energy waste

Insulated sectional doors cause air convection between the interior and exterior when opened, especially during winter heating or summer cooling. Frequent opening and closing of the door results in a loss of temperature control and a loss of energy, which ultimately increases the operating costs of the organization.

Temperature Control Imbalance: In cold winter, once the indoor heating is disturbed by the cold outside air, the heating system needs to work extra to maintain the temperature. While in hot summer, the air conditioning equipment increases energy consumption due to cold air leakage.

Efficiency and Environment

In order to prevent the intrusion of pollutants and reduce energy waste. Many factories choose to reduce the frequency or speed of door opening, which directly affects the efficiency of forklift trucks and personnel. Increasing the speed and frequency of door opening can speed up the production process, but it may also increase energy consumption, creating a conflict between efficiency and environment.

Balancing Operational Efficiency and Environmental Protection: In some factories, managers often have to make difficult choices between environmental protection and production efficiency. If the sectional industrial sectional door opens too slowly or infrequently. And the production line will be inefficient; if the door opens and closes frequently. It will lead to energy waste and increased environmental pollution.

Sectional Door & Air Curtain:How is the Synergistic Effect of 1+1 > 2 Achieved?

How Sectional Doors and Air Curtains Work

In many industrial and manufacturing environments. Sectional Overhead Doors act as a physical partitioning device to efficiently separate different areas to ensure temperature control and cleanliness. Air Curtains, on the other hand, utilize high velocity airflow to form a barrier that effectively isolates outside contaminants and air exchange. When the two are used independently, although they can solve certain environmental control problems separately. They are not able to achieve the best in terms of energy saving and effectiveness. Their linked application brings many advantages to a building, including improved indoor air quality, energy savings, and enhanced building safety.

Their workflow is typically as follows:

- When doors are closed: The industrial sectional doors is in the closed position, providing physical isolation, security against burglary and thermal insulation. At this time, the air curtain machine is in standby or off state, does not consume energy.

- When the door opens: When the industrial sectional door receives the opening signal (e.g. remote control, radar, ground sensor) and starts to run upwards. The linkage controller will start the air curtain machine immediately.

- When the door is fully open: the industrial sectional doors reaches the top and the physical barrier disappears. However, at this time, the air curtain machine has been running at full speed, blowing a strong, uniform downward airflow from the top of the doorway, forming an “invisible air door”.

- Formation of airflow barrier: This high-speed airflow barrier can effectively prevent outdoor dust, insects, exhaust gases, etc. from entering the room, and also prevent the indoor cold/warm air from escaping. Forklifts and personnel can pass through quickly and without obstacles.

- When door closes: When the industrial sectional doors begins to close. The controller delays for a few seconds before shutting down the air curtain, ensuring that the airflow barrier remains in effect until the door is fully closed. When the door is fully closed, the air curtain machine automatically stops and returns to energy-saving standby mode.

Core Advantages of the Combo Solution: Elevating Factory Operational Standards

Achieving Superior Cleanliness & Contaminant Control

Through an intelligent linkage system, air curtains & sectional doors effectively form an airflow barrier, preventing external dust, insects, exhaust gases and other contaminants from entering the production area and ensuring a clean workshop environment. This solution is particularly suitable for the food processing and pharmaceutical industries, ensuring product quality while effectively reducing cleaning costs. The linkage between the air curtain and the lift door ensures that outside contamination cannot easily enter. And at the same time provides a continuous dust and insect control effect to maintain a clean factory environment.

Significantly Reducing Energy Consumption & Saving Costs

Through the air barrier of the air curtain machine. The loss of hot and cold air is effectively reduced, which reduces energy consumption. In environments with large temperature differences. The linkage of air curtains and sectional lift doors reduces air convection and saves energy in the factory. This solution not only helps the factory save energy expenses.. But it also improves the stability of the temperature-controlled area, ensuring that the temperature and humidity in the workshop remain in the ideal range.

Ensuring High Efficiency Logistics & Eliminating Bottlenecks

Intelligent linkage ensures the smooth flow of logistics in the workshop. In this way, forklift trucks and personnel are able to pass quickly, reducing the waiting time caused by frequent door opening and closing. The linkage of air curtains and industrial sectional doors meets the factory’s need for efficient logistics. And avoids production stoppages or logistics bottlenecks caused by traditional door systems.

Improving Employee Working Environment & Comfort

The air curtain machine provides stable temperature and fresh air for the workshop by effectively isolating the external pollution sources, ensuring that employees work in a comfortable environment. By reducing interference from outside sources. The working environment inside the factory is significantly improved, creating a healthier and more productive workplace.

FAQ

Q: Is sectional overhead door linked system with an air curtain really better than using an air curtain alone?

A: Yes, the effect is much better. An air curtain alone has a diminished airflow barrier effect when the doorway is left open for long periods of time. The core advantage of linking a sectional steel door with an air curtain machine. It activates the air curtain machine only for the briefest of moments when the door is open, minimizing the physical opening time of the door opening.

Q: Our factory is a GMP pharmaceutical plant, can this linkage system meet our cleanliness and compliance requirements?

A: Absolutely. This linkage system is ideal for Pharma factory environment control. We can provide a program designed specifically for clean environments:

- Steel sectional doors with smooth, easy-to-clean, food-grade or GMP workshop doors with stainless steel hardware.

- Air curtains are available in clean models with stainless steel housings to prevent self-generated dust.

- Linkage logic can help maintain the positive or negative pressure environment required by the GMP workshop. Effectively preventing cross-contamination and helping companies to meet GMP, HACCP and other industry certifica

Q: For cleanroom entrances in semiconductor factories, does this linked system provide ESD protection?

A: Yes, this is a key benefit of the system for cleanroom doors for electronics applications. We can offer specialized ESD-safe speed doors with anti-static PVC material. When it is linked with an air curtain, you will get excellent particulate control and temperature and humidity stabilization while also providing the necessary protection for electrostatic sensitive devices.

Q: Will air curtains be noisy enough to affect the workshop working environment?

A: This is a good question. Modern Industrial Air Curtains are designed with noise control in mind. Although air curtains need to have sufficient air volume and speed to form an effective airflow barrier. Quality brands will keep the operating noise within reasonable. Industrial environmental standards by optimizing the design of the wind turbine, using high quality motors and noise-reducing housings, and so on. We can recommend the most suitable low-noise model according to your specific requirements on noise level.