In the fast-paced industrial operations, every detail matters—especially when it comes to your warehouse infrastructure. The right warehouse shutter doors are more than just entry points. These essential components do more than just open and close; they safeguard your inventory, streamline operations, and even impact your bottom line.

This article is your complete guide to modern warehouse shutter door solutions. Whether you’re upgrading an aging facility or planning a new build. You’ll discover how smart door choices can save costs, boost security, and streamline operations.

Contents

- 1 Market Landscape & Industry Overview: Trends Shaping the Warehouse Door Market

- 2 Comprehensive Guide to Warehouse Shutter Doors Types

- 3 Strategic Buyer’s Guide: Making the Right Choice

- 4 Professional Installation & Maintenance Excellence

- 5 Leading Warehouse Shutter Doors Manufacturers in Global Market

- 6 Conclusion: Making the Smart Investment

Market Landscape & Industry Overview: Trends Shaping the Warehouse Door Market

The warehouse door market is expanding globally, driven by strong growth in e-commerce, logistics, and industrial sectors. Current valuations place the market in the multi-billion dollar range, with projections indicating continued upward momentum in the coming years. Regional demand is led by North America, Europe, and Asia-Pacific, reflecting robust supply chain and manufacturing activities.

Key segments include warehouses, distribution centers, manufacturing facilities, and cold storage, each contributing significantly to industrial door demand. The main drivers of this growth are the rapid rise of e-commerce, increased adoption of automation, stricter energy efficiency requirements, and heightened security and safety regulations. Together, these factors are shaping new opportunities and setting the direction for the future of the warehouse door industry.

Comprehensive Guide to Warehouse Shutter Doors Types

Roll-Up Doors: The Versatile Standard

Roll-up doors are a fundamental component of the warehouse shutter door market, providing versatility and reliable functionality for a wide range of industrial applications.

- Steel Roll-Up Doors: Known for their maximum security and durability, these doors are ideal for high-security warehouses.

- Aluminum Roll-Up Doors: Lightweight and corrosion-resistant, making them perfect for environments with high moisture levels.

- Fabric Roll-Up Doors: Designed for high-speed and flexible applications, these doors are commonly used in areas with frequent traffic.

- Insulated Roll-Up Doors: Provide climate control and energy savings, reducing operational costs while maintaining temperature stability.

Benefits of Insulated Roll-Up Doors for Your Warehouse

- Maximum Security: Steel roll-up doors are a great way to keep your space secure, making them perfect for high-security warehouses.

- Durability: Built to withstand harsh industrial environments, these doors resist wear and tear, ensuring long-term reliability.

- Low Maintenance: Their robust construction reduces frequent repairs, saving time and costs.

Sectional Overhead Doors

Sectional overhead doors are a space-saving warehouse door solution, designed to fold neatly into the ceiling when opened. This makes them ideal for maximizing space in industrial or commercial settings, while also ensuring smooth and efficient operation.

Advantages of Sectional Overhead Doors in Industrial Applications

- Space Efficiency: These warehouse sectional doors fold neatly into the ceiling, freeing up valuable floor space for operations or storage.

- Easy Maintenance: The sectional design enables quick and cost-effective repairs by allowing individual panels to be replaced without the need to replace the entire door.

- Enhanced Pest Control: Provides a tight seal to prevent pests and contaminants from entering the facility.

High-Speed Roller Doors

High-speed warehouse doors offer fast operation that boosts efficiency in busy spaces. These doors are designed with advanced features, such as enhanced safety mechanisms, durable materials, and energy-efficient insulation, making them an ideal choice for warehouses, factories, and other high-traffic facilities.

Benefits of High-Speed Doors for Warehouse Facilities

- Traffic Flow Optimization: Reduces bottlenecks in high-traffic areas.

- Self-Repairing & Impact-Resistant Features: Minimizes repair costs and downtime.

- Energy Conservation Control: Maintains internal temperatures, reducing energy consumption.

Steel Hinged Doors

Steel hinged doors are a robust and reliable option for warehouses that require enhanced security, durability, and long-term performance. Designed to withstand heavy use and resist damage, these doors provide superior protection against unauthorized access while also withstanding harsh industrial environments. Ideal for high-traffic areas, they ensure both safety and peace of mind for warehouse operations.

Benefits of Steel Hinged Doors for Warehouse Settings

- High resistance to wear and tear.

- Superior security for restricted areas.

- Cost-effective and long-lasting.

| Door Type | Security | Durable | Energy | Speed | Custom | Rating |

| Steel Roll-Up Door | ★★★★★ | ★★★★★ | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ | ★★★★★ |

| Aluminum Roll-Up Door | ★★★★☆ | ★★★★☆ | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ | ★★★★☆ |

| Fabric Roll-Up Door | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ | ★★★★★ | ★★★☆☆ | ★★★★☆ |

| Insulated Roll-Up Door | ★★★★☆ | ★★★★☆ | ★★★★★ | ★★★☆☆ | ★★★☆☆ | ★★★★★ |

| Sectional Overhead Door | ★★★★☆ | ★★★★☆ | ★★★☆☆ | ★★★☆☆ | ★★★★★ | ★★★★☆ |

| High-Speed Door | ★★★★☆ | ★★★★☆ | ★★★★★ | ★★★★★ | ★★★★☆ | ★★★★★ |

| Steel Hinged Door | ★★★★★ | ★★★★★ | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ | ★★★★☆ |

| Fire-Rated Door | ★★★★★ | ★★★★★ | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ | ★★★★★ |

Strategic Buyer’s Guide: Making the Right Choice

Selecting the right warehouse doors is a critical decision that impacts operational efficiency, security, and long-term costs for any industrial facility. With multiple types, features, and price points to consider, it’s essential to approach this purchase with a strategic mindset. This warehouse door buying guide is designed to help you assess your facility’s needs, analyze costs, and make confident, informed decisions.

Needs Assessment Framework

Before choosing a door, thoroughly understanding your facility’s requirements ensures a better match between functionality and investment. Here’s how to evaluate your specific needs:

Facility Requirements & Usage Analysis

- Identify which zones of your warehouse need doors—loading docks, cold storage areas, or clean rooms.

- Evaluate the door size and type requirements based on your operation, from small access doors to large sectional or rolling doors.

Traffic Volume & Frequency Considerations

Assess the volume of traffic passing through daily. Loading zones with high forklift activity may benefit from high-speed doors, while low-traffic areas might only require sectional overhead doors.

Environmental Factors & Climate Needs

- Consider external conditions—does the location face extreme temperatures or exposure to wind and moisture?

- For sensitive goods, such as food or pharmaceuticals, insulated doors or cold storage doors ensure proper climate control and energy efficiency.

Security Level Requirements

Warehouses with high-value inventory need doors with enhanced security, such as steel roll-up doors or blast-resistant doors, which offer superior protection against unauthorized access or external threats.

Budget Planning & ROI Calculations

Allocate resources for both upfront costs and long-term savings. For example, industrial door cost analysis reveals that insulated doors can have higher initial costs, but yield energy savings over time.

By successfully mapping out these considerations, you’ll be set up to make a smarter purchase decision aligned with your operational demands.

Comprehensive Cost Analysis of Warehouse Shutter Doors

Investing in warehouse doors isn’t just about the price tag—it’s about evaluating the overall value and impact on your operations. This section provides actionable insights into industrial door cost analysis for a 360-degree understanding of expenses.

Initial Purchase & Installation Costs

The cost of commercial doors ranges vastly by type and material. Expect to pay between $200 and $2,500 per door, plus installation fees, which depend on labor rates and customization requirements.

Operating Expenses & Energy Consumption

- Insulated doors lower energy costs by maintaining internal temperatures, particularly suitable for climate-sensitive warehouses.

- Assess the daily operating cost; manual doors are cheaper to run but less efficient for high-traffic areas compared to automated solutions.

Maintenance & Repair Cost Projections

- Some door types, like high-speed fabric doors, offer self-repairing features, cutting down long-term repair costs.

- Factor in routine maintenance such as lubrication, alignment checks, and potential panel replacements.

Productivity Impact & Efficiency Gains

Faster doors translate to smoother workflows and increased efficiency in busy environments. For instance, high-speed models significantly reduce vehicle idle times at loading bays, allowing quicker turnarounds and optimizing productivity across operations. These doors are especially beneficial in industries where time is critical, such as logistics, manufacturing, and warehousing.Additionally, well-functioning doors help prevent downtime caused by unexpected breakdowns or delays in daily operations. Regular maintenance and advanced door systems ensure seamless functionality, keeping your business running without interruptions and avoiding costly setbacks.

- Well-functioning doors minimize downtime caused by breakdowns or delays in daily operations.

Total Cost of Ownership (TCO) Analysis

Combine all the above expenses to calculate the TCO. While insulated or blast-resistant doors may require more investment upfront, their durability and efficiency offer better long-term ROI.

Selection Criteria & Decision Matrix

Making the final selection comes down to thoroughly evaluating your options against a set matrix of performance and vendor considerations. Use these critical factors to ensure the most strategic decision:

Performance Requirements Checklist

Does the door meet your specific needs for speed, durability, and security?

Is it compatible with your operational requirements, such as frequent use or exposure to harsh environments?

Vendor Evaluation & Comparison

- Research vendors’ reputations and reviews, focusing on quality, reliability, and customer support.

- Compare quotes to find cost competitiveness without compromising on crucial features.

Warranty & Service Support Analysis

- Look for warranties that cover both parts and labor. For critical doors like cold storage models, extended coverage is ideal.

- Confirm post-sale service options, such as maintenance plans or emergency repairs, to avoid future gaps in support.

Implementation Timeline Planning

Work with the supplier to schedule the door installation at a time that aligns with your business operations. Plan your workflows to minimize disruptions during the installation process. By coordinating effectively, you can ensure a smooth door installation with minimal impact on productivity.

Choosing the right warehouse roller shutter door requires a balance of functionality, cost-effectiveness, and long-term reliability. By following this structured buyer’s guide, you can compare key options effectively, from insulated roll-up doors for energy savings to high-security blast-resistant solutions. Always prioritize operational efficiency, aligned security, and total cost value for the best investment in your facility’s future.

Professional Installation & Maintenance Excellence

Warehouse roll up doors are among the most critical components in an efficient industrial operation. Proper installation and maintenance not only ensure smooth operation, but also prolong the lifespan of the doors and enhance safety. This comprehensive guide dives into key aspects of installation, maintenance, and troubleshooting to help you achieve operational excellence.

Installation Best Practices

Site Assessment & Preparation

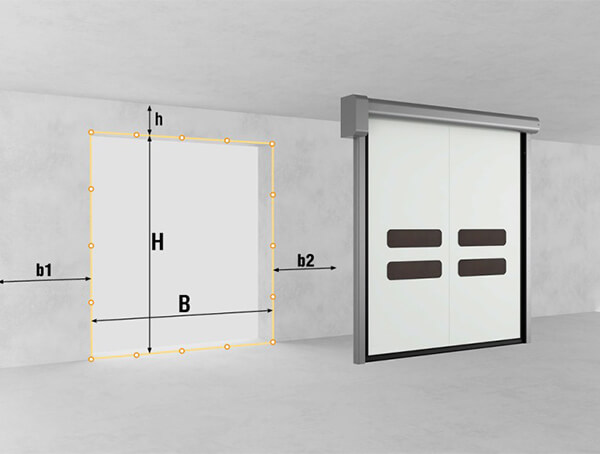

A successful door installation starts with a thorough site assessment. Examine the space for any obstructions and measure dimensions accurately to ensure the door fits seamlessly. Consider environmental factors like humidity, temperature, or exposure to corrosive substances that may impact the door’s material or performance. Preparing the site involves clearing debris, ensuring floor leveling, and checking wall and ceiling conditions. Site preparation helps mitigate issues during and after installation.

Structural Requirements & Modifications

Warehouse doors require robust structural support. Before installation, assess the existing framework to ensure it can bear the weight and operational stress of the door. For heavier doors or high-usage conditions, additional structural reinforcements might be needed. Always use suitable anchors and mounting hardware rated for industrial environments.

Electrical & Control System Integration

Many modern warehouse roller doors feature automation. Wiring, control panels, and integration with existing systems must not only comply with operational specs but also support features like remote control, motion sensors, and emergency overrides. Coordinate with electricians to ensure proper voltage and safe cable routing.

Safety Compliance & Code Requirements

Safety is vital during warehouse door installations. Installers must adhere to relevant OSHA standards, local building codes, and industry specifications. Features like fail-safe mechanisms, emergency stops, and alignment sensors often form part of compliance protocols.

Using warning decals and ensuring guards for moving components also enhance safety measures. Regularly inspecting installations against code checklists ensures ongoing compliance.

Testing & Commissioning Procedures

Thorough testing is essential before commissioning the door for use. Evaluate door alignment, test motor functionality, and check sensors and controls. Conduct repeated open-close cycles to identify resistance points or misalignments. Once all components are verified, document the operational tests to provide a benchmark for future maintenance.

Maintenance Program Development

Preventive Maintenance Schedules

A well-implemented preventive maintenance program minimizes breakdowns and prolongs the life of the door. Schedule inspections monthly or quarterly based on the usage level. A maintenance log helps track completed tasks and identify patterns in wear and tear over time.

Inspection Protocols & Checklists

Inspection protocols form the backbone of effective maintenance. Include points like roller alignment, track integrity, spring tension, and hinge wear. Adding regular motor diagnostics for automated systems ensures the operational consistency of the mechanism.

Lubrication & Cleaning Requirements

Moving parts like rollers, hinges, and tracks require regular lubrication with appropriate industrial-grade grease. Cleaning the tracks and removing debris prevents obstruction and ensures smooth operation. Performing this step at least once a month keeps mechanical components in top shape.

Component Replacement Guidelines

Parts like springs, rollers, and weather stripping see the most wear and tear. Create guidelines for identifying faulty components and their timely replacement. Always use high-quality, manufacturer-approved replacements to maintain system integrity and safety.

Emergency Service & Repair Procedures

Despite preventive measures, emergencies can arise. Include an accessible plan detailing steps like manually securing the door and contacting service providers. A 24/7 emergency repair contract may prove invaluable in avoiding downtime.

Troubleshooting & Common Issues

Diagnostic Procedures & Problem Identification

For smooth troubleshooting, start with a systematic diagnostic approach. Look out for symptoms like unusual noises, slower movement, or misalignment. Use problem-specific tools like tension testers or alignment gauges to pinpoint the root causes.

Common Failure Points & Solutions

Breakdowns often occur at predictable points. Rollers may jam, tracks might bend, and motors can fail over time. Keeping essential spare parts onsite can minimize repair time. For example, stock extra rollers, fasteners, and a replacement motor battery.

Performance Optimization Tips

Optimize door performance by calibrating sensors for automatic systems and conducting regular alignment checks. Upgrading older motors to energy-efficient models reduces operational costs and extends usability.

When to Call Professional Service

Some issues, like cracked panels, complex system malfunctions, or persistent motor failures, warrant professional attention. Trained technicians provide advanced diagnostic tools and expertise to resolve such problems quickly and correctly.

Leading Warehouse Shutter Doors Manufacturers in Global Market

Warehouse shutter doors play a critical role in enhancing facility security, optimizing operational efficiency, and withstanding demanding industrial conditions. These doors are essential for various industries, from logistics and manufacturing to retail and beyond. The global market for warehouse shutter doors is dominated by key players who have set the bar high in terms of quality, innovation, and performance. This post highlights the top manufacturers globally, exploring their contributions, unique strengths, and innovations that keep them ahead of the competition.

ASSA ABLOY Entrance Systems

ASSA ABLOY Entrance Systems is a global powerhouse in the industrial door sector. With its roots going back decades, the company has continuously developed its portfolio to meet evolving market demands. Known for its comprehensive range of solutions, ASSA ABLOY specializes in high-speed doors, industrial rolling shutters, and dock levelers.

Their ongoing commitment to improving productivity and safety has made them a preferred choice for industries requiring heavy-duty shutter doors.

Overhead Door Corporation

Overhead Door Corporation is a trusted name in the industrial door way product ecosystem. A pioneer with over a century of experience, the company has an impressive catalog that includes rolling steel doors, fire-rated shutters, and high-performance doors.

By balancing innovation with a solid foundation of craftsmanship, Overhead Door Corporation continues to be a leader in the field.

Hormann Group

Hormann Group is a globally recognized brand specializing in doors and gates for industrial applications. Headquartered in Germany, Hormann is renowned for its precision engineering and robust product lines, which include industrial sectional doors, high-speed options, and rolling shutters.

Constantly pushing the boundaries of innovation, Hormann Group is revered for reinforcing industrial safety, efficiency, and convenience through its versatile solutions.

Rite-Hite Corporation

Based in the United States, Rite-Hite Corporation specializes in loading dock equipment and high-speed industrial doors. Since its establishment, the company has focused on optimizing warehouse and distribution capabilities for businesses of all sizes.

Their robust product portfolio and focus on improving warehouse functionality solidify their place as an industry leader.

SEPPES Door Industry

Rising from China, SEPPES Door Industry has become an emerging powerhouse in the global industrial door market. Specializing in high-speed shutter doors, SEPPES caters to industries that require efficient and reliable access systems.

Despite being a newer player, SEPPES has rapidly gained traction by emphasizing technological advancement and affordability.

The global market for warehouse shutter doors is shaped by manufacturers who constantly strive to deliver exceptional products through innovation and lasting value. ASSA ABLOY Entrance Systems, Overhead Door Corporation, Hormann Group, Rite-Hite Corporation, and SEPPES Door Industry stand out not just as leaders, but as driving forces propelling the industry forward. Their combined contributions ensure smoother operations, enhanced security, and greater efficiency across industries worldwide.

Conclusion: Making the Smart Investment

Choosing the right warehouse door is a critical business decision. Focus on security, energy efficiency, durability, and operational needs when making your selection. Review your facility’s requirements, compare door types using credible data, and prioritize features that support your long-term goals.