When it comes to choosing the right industrial door system, many businesses and factories are faced with an important decision: high speed pvc door vs sectional door? Both types of industrial doors have their own characteristics and are widely used in different industries and environments. Which door type to choose is not only about the efficiency of day-to-day operations. But also about energy consumption, safety, durability and the difficulty of installation and maintenance.

This article provides a direct comparison between High Speed PVC Door and Sectional Door, helping you better understand their respective advantages and disadvantages. It will analyze their performance in different application scenarios, allowing you to make the best choice based on your specific needs. With this guide, you will gain insights into which door system best meets your requirements, enabling you to make an informed decision.

Contents

Design and Structure Comparison of High-Speed PVC Doors and Sectional Doors

High-Speed PVC Door

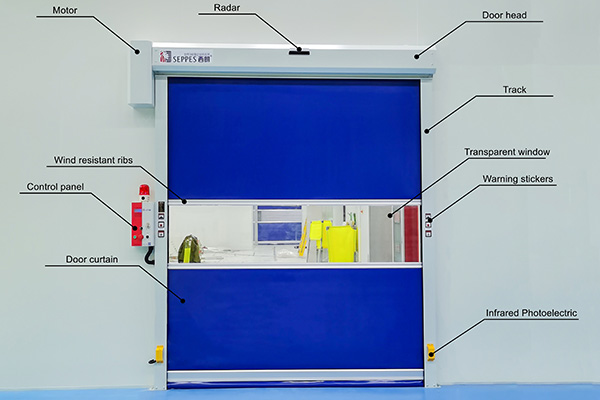

High-Speed PVC Doors are typically made from flexible PVC materials, offering adaptability and flexibility. Their design focuses on efficient operation with rapid opening and closing movements that significantly enhance workflow speed. These doors are designed to be sleek and modern, ideal for environments that require frequent opening and closing. Due to their lightweight structure, PVC rapid roller doors generally do not require complex track systems, making them easier to install.

Sectional Door

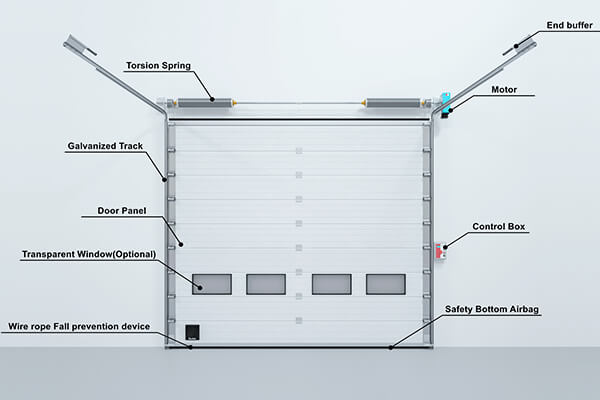

Sectional Doors consist of multiple independent panels that move up and down along vertical tracks. The structure is more robust, typically made from steel or aluminum alloy materials. Sectional overhead doors are designed to be heavier and more solid, making them suitable for locations that require higher security and insulation. Their segmented structure provides excellent wind resistance, making them especially suited for external environments where weather conditions can be more challenging.

High-Speed Doors vs. Sectional Doors: Key Differences

| Feature Comparison | Sectional Door (The Traditional Workhorse) | High-Speed Door (The Productivity Driver) |

| Defining Feature | Constructed from rigid, interlocking horizontal panels that lift vertically. Built for security and durability. | Engineered for rapid open/close cycles, typically using a flexible curtain or lightweight panels. Built for speed and efficiency. |

| Key Advantages | ● High Security & Durability: Solid panels provide a formidable physical barrier against intrusion and impact. ● Cost-Effective: Lower initial purchase price compared to high-speed models. ● Excellent Insulation: Options for thick, insulated panels offer high R-values for superior thermal control. | ● Exceptional Speed: Maximizes traffic flow, eliminates bottlenecks, and boosts overall productivity. ● Superior Energy Savings: Minimal air exchange significantly reduces HVAC costs. ● Enhanced Environmental Control: Creates a tight seal against dust, pests, and contaminants. |

| Key Limitations | ● Slow Operating Speed: Creates wait times, slows down operations, and leads to significant energy loss. ● High Maintenance Needs: Complex mechanical parts like springs, cables, and rollers require frequent inspection and replacement. | ● Higher Initial Investment: Requires a larger upfront capital expenditure. ● Different Security Profile: A flexible curtain offers less physical intrusion resistance than solid panels. |

| Best-Fit Applications | ● Exterior Loading Docks: Especially for overnight security. ● Low-Traffic Doorways: Where speed is not a critical factor. ● Applications Where Budget is the Primary Concern: And a basic, reliable door is sufficient. | ● High-Traffic Interior & Exterior Doorways: To maintain a constant flow. ● Climate-Controlled Environments: Such as cold storage, food processing, and cleanrooms. ● Automated Facilities: Where seamless integration with conveyors or AGVs is needed. |

Making the Right Choice: Your Application-Specific Guide

For Interior Applications

For internal passages separating warehouses, production areas, clean rooms or different temperature zones. Your choice should be based on the traffic flow and the strictness of the environmental controls.

When to choose high speed roll up door?

- High-traffic area: If this is the main corridor connecting the warehouse to the production line, with hundreds of forklift or personnel movements per day, then a speed door is the only logical choice. Its high-speed circulation eliminates traffic bottlenecks and maximizes overall operational efficiency.

- Strict Environmental Control: In areas such as food processing, pharmaceutical or electronics manufacturing where temperature, humidity or cleanliness needs to be tightly controlled. The excellent sealing and short opening times of speeds door are key to maintaining a stable environment.

- Cold Storage and Temperature Zones: Installing insulated sectional door at the entrance to a cold storage facility can dramatically reduce cold air loss and frosting problems,. And the long-term payback from the energy savings can be significant.

When to choose industrial sectional doors?

- Low-traffic or storage areas: Industrial sectional doors are more cost-effective when an internal passageway is only opened a few times a day, such as to an infrequently used storage room or equipment room.

- Budget is a priority: When operational efficiencies and environmental controls are not critical. And budgets are extremely limited, sectional doors can fulfill basic partitioning needs with a much lower initial investment.

For Exterior Applications

Exterior doors not only have to cope with heavy traffic, but also weatherproof and secure.

When to choose high speed roll up door?

- Loading dock area: For logistics centers and distribution warehouses, efficiency at dock area is a lifeline. Exterior rapid doors can dramatically reduce vehicle wait times for each load and unload. While closing quickly after the trucks leave, keeping out inclement weather, dust and flying insects.

- Energy Cost Sensitive Facilities: If your facility is located in an area with a volatile climate. The energy savings provided by exterior sectional doors can be significant, directly reducing your heating and cooling bills.

When to choose insulated sectional doors?

- Nighttime Security: The rugged panel construction of industrial sectional doors provides physical security. It remains a reliable choice for exterior entrances and exits that prioritize safety over efficiency.

- Exits with minimal traffic: The robustness and low cost of sectional doors are key advantages for exterior doors used only as emergency exits or for access to infrequently used equipment.

Ultimately, there is no single answer to the debate between high-speed fabric doors and insulated sectional doors – only the solution that best suits the operational needs of your plant and business.

A sectional door remain a reliable and cost-effective option for low-traffic areas where security and initial budget are key considerations. It is a traditional workhorse with excellent durability and insulation.

In contrast, high-speed pvc door is an investment in productivity, efficiency and long-term energy savings. For any facility where traffic flow and environmental control are important. The benefits of speed and automation will lead to high efficiency.

Before making a final decision, take the time to carefully evaluate your facility’s daily foot traffic, environmental requirements and long-term operational goals.